Meta Title: Shockproof Phone Cases: Do Drop Tests Matter for Protection?

Meta Description: Quit throwing money away on false protection! Actual drop test statistics uncover which shockproof phone case materials safeguard against costly screen damage.

URL: drop-resistant-phone-cases-testing-standards-guide

When shoppers drop their phones and watch in horror as screens spider-web into a thousand cracks, they immediately understand that a shockproof phone case is not so much an accessory as it is mandatory insurance. The “airbag” technology of newer phone cases is the difference between a close call and an expensive repair bill that can be upwards of hundreds of dollars.

How Do Drop-Resistance Ratings Really Function within Shockproof Phone Cases?

International Testing Standards Analysis

Learning about protection levels involves being familiar with some testing standards. The MIL-STD-810G military standard subjects cases to rigorous 1.2-meter multi-angle drop testing that simulates real accident scenarios. These tests determine how well cases protect devices when they fall on various surfaces and at different angles.

IP ratings also give more information about dust and water resistance levels. Though not the direct concern of drop protection, these ratings tell us about the overall build quality and consideration for environmental dangers phones are exposed to every day.

Third-party certification by companies such as SGS or Intertek offers independent verification of protection claims, assurance to sellers and consumers of performance specifications.

Scientific Principles Underlying Good Design

Contrary to popular belief, better drop protection does not have to come with excess weight or bulk. Modern materials science has developed solutions that absorb and dissipate impact energy through intelligent design instead of brute mass.

Advanced shockproof phone cases use some cool science to spread out the energy from impacts, which keeps the important parts of your phone safe. This means they can b

e sleek and look good while still being super protective. The trick is figuring out how various materials and designs react to sudden hits and making them that way.

What Materials and Design Features Make Shockproof Phone Cases Really Effective?

Comparing How Different Popular Materials Perform

Polycarbonate (PC) contributes to superior hardness that resists penetration and retains structural integrity under impacts. Its rigidity makes it well-suited for outer shells that must keep their shape when stressed.

Thermoplastic Polyurethane (TPU) provides excellent elasticity with superior shock absorption. Being flexible, it compresses on impact and restores its original shape, dispersing energy that would have otherwise been transferred to the device.

The most effective shockproof phone cases combine these materials strategically, using PC for structural elements and TPU for impact zones. This composite approach maximizes the benefits of each material while minimizing its individual limitations.

Innovative Protective Structure Analysis

Air-cushioned corner designs focus on protection where phones most typically strike surfaces. These strengthened corners serve as initial energy absorbers, sparing device edges and screens from damage.

Honeycomb internal structures are inspired by nature’s most optimal designs. The patterns spread impact forces over larger areas while keeping weight to a minimum, developing superior strength-to-weight ratios.

Multi-level airbag systems create progressive energy absorption, with outer layers handling initial impact and inner layers providing secondary protection. This stepped approach prevents force concentration that could overwhelm any single protective element.

Elevated bezels around cameras and screens provide essential standoff distances that avoid direct surface contact when dropping face down. This basic design feature eliminates impact damage and scratches to the most sensitive device elements.

Real-World Testing Validation

Extensive drop testing at multiple heights shows how cases stand up to a range of impact energies. Testing labs perform professional evaluations using calibrated equipment and standard procedures that yield repeatable, dependable results.

Environmental testing replicates extreme temperatures that influence material characteristics. Instances that work optimally under lab conditions can fail under actual temperature extremes, and hence, the testing is important for quality assurance.

Long-term durability testing evaluates how repeated impacts affect protective capabilities over time. This testing identifies potential failure modes and ensures that shockproof phone cases maintain their protective properties throughout their expected lifespan.

Why Is Protection Your Number One Selling Point for Shockproof Phone Cases?

Real Issues Consumers Experience

Statistics actually demonstrate just how exposed mobile devices are. A screen replacement typically ranges from 30% to 50% of the original cost of the phone, and for top-end models, the repair often exceeds $300. Due to this, individuals’ priorities have completely shifted, and recent surveys have found that 85% of consumers now consider protection to be the top priority when they’re selecting a phone case.

Smartphones today have grown more vulnerable as companies chase thinner profiles and bigger displays. The outcome is products that are more likely to get damaged from normal drops and bumps. Consumers learned this lesson the hard way, and thus, a market need for truly protective cases instead of just decorative ones was created.

Sellers’ Concealed Expense

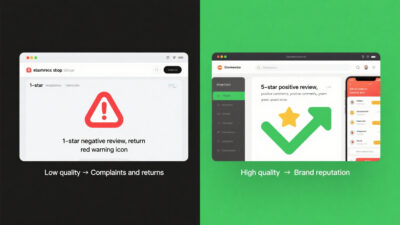

Quality problems cause chain reaction issues that reach well beyond the point of first sale. One bad batch of phone cases can generate 20 customer complaints, returns, and damaging reviews that harm long-term reputation. Analysis within the industry indicates that processing one quality-related complaint can erase the profit from 10 good orders when considering customer service time, replacement costs, and future lost sales.

The ripple effects reach brand image and customer loyalty. Sellers who consistently sell quality shockproof phone cases gain credibility that leads to repeat business and positive word-of-mouth recommendations, whereas those who compromise on quality have an uphill task in regaining credibility.

How Can Sellers Reduce Risk When Choosing Shockproof Phone Case Suppliers?

Purchasing Risk Assessment Framework

Quality indicator screening necessitates methodical assessment of material consistency, manufacturing accuracy, and design integrity. Sellers ought to have definitive acceptance standards for each of these factors and implement them uniformly on all possible suppliers.

Basic field test procedures can identify quality problems before they reach consumers. Drop testing with real devices, flexibility tests, and fit tests offer real-world insight into actual performance.

Supplier qualification audits need to review the manufacturing capabilities, quality systems, and adherence to applicable standards. Such due diligence upfront avoids downstream costly issues and assures repeat product quality.

Maximizing Partnership Value

Phone case supplier relationships of long duration, founded on quality principles, yield better outcomes than those based solely on price considerations. Good suppliers offer consistent quality, responsive customer service, and adept problem-solving when things go wrong.

Continual dialogue regarding product enhancements, market directions, and customer feedback generates two-way benefits that enhance business relationships and product offerings over time.

Frequently Asked Questions

Q1. What’s the Difference Between Military-Grade Phone Cases and Normal Ones?

Military-grade cases go through the wringer with these MIL-STD-810G tests, which test how they fare when dropped, when the temperature changes, and with all kinds of environmental factors. Normal cases may offer some protection, but they haven’t passed those military testing hurdles. When a case has the military-grade label, it’s been through some rigorous tests that simulate harsh conditions and every type of impact, so you know it can withstand a beating.

Q2. How Do Air Cushion Features Actually Protect Phones During Drops?

Air cushion technology works by creating compressible zones that absorb impact energy before it transfers to your device. When a phone hits the ground, these air-filled chambers compress and expand, converting kinetic energy into harmless deformation rather than allowing it to reach sensitive components. The cushioning effect is similar to automotive airbags, creating a buffer zone that significantly reduces the forces transmitted to the phone’s internal components and screen.

Q3. Can Thin Shockproof Phone Cases Provide the Same Protection as Bulky Ones?

Modern materials science has enabled thin cases to deliver excellent protection through strategic design and advanced materials rather than bulk. The key factors are material properties, structural engineering, and energy distribution patterns. A well-designed thin case using high-quality TPU and PC materials with proper reinforcement can outperform a thick case made from inferior materials. Protection depends more on how impact energy is managed than on overall case thickness.

Q4. Why Do Some Highly Rated Shockproof Phone Cases Break on Drops?

Case failure is most commonly caused by manufacturing flaws, material deterioration, incorrect installation, or drops in excess of design specifications. All cases, even highly rated ones, have their limits, and the angle of impact, surface hardness, and drop height all play a role in the outcome. Cases also degrade over time due to material fatigue, UV, or compounding damage from prior drops. Periodic inspection and replacement guarantee ongoing protection.

Q5. How Frequently Must Shockproof Phone Cases Be Replaced to Ensure Maximum Protection?

Expert guidelines propose the following replacement every 12-18 months for general users, or earlier if there is noticeable damage. More intensive use settings can call for more frequent replacement. Indications that a replacement is needed include apparent cracks, permanent deformation, loose fit on the device, or loss of flexibility in TPU parts. Cases that have cushioned phones from major drops should be examined immediately and possibly replaced, since the force of the impact could have weakened their structural integrity.

Conclusion about Shockproof Phone Cases

The “airbag” concept in shock-absorbing phone cases is more than a marketing gimmick—it’s an engineering solution with a track record that saves consumers hundreds of dollars in repair while shielding sellers from quality complaints and returns. Intelligent sellers who value real protection over cosmetic features earn customer loyalty and minimize long-term business risks.

Ready to provide your customers with better protection and reduce your business risk? Runsuncase is a professional phone case source factory with 20 years of OEM/ODM experience, focusing on drop protection technology development. We provide varied phone case products for iPhone, Samsung, and other brands, such as carbon fiber, Kevlar, magnetic wallet series, all with high-quality TPU+PC material and airbag cushioning design. We support custom logo packaging with 100% professional QC, helping to bring cost-effective protection solutions to overseas independent brands. Contact our team today to obtain detailed test reports, arrange product samples, and learn how our quality assurance program can enhance your phone case offering. Join the growing network of sellers who’ve made protection their competitive edge.