The demand for stylish and high-quality phone cases has been skyrocketing. Consumers now want phone cases that not only protect their devices but also reflect their personality and style. This trend has driven phone case manufacturers to explore new production technologies. One of the most innovative methods is IML (In-Mold Labeling). But how did an IML technology phone case come into being? Let’s take a closer look.

The Origins of IML Technology

IML technology was not originally developed for phone cases. It started in the packaging industry in the 1970s. Manufacturers used IML to create high-quality labels on containers like food packaging and household products. The process offered vibrant colors, durability, and efficiency — qualities that traditional printing methods could not match.

As IML technology evolved, its potential in other industries became clear. Over time, production case companies recognized that IML could offer significant benefits for the phone case market. The ability to embed a design within the plastic itself provided a superior finish and lasting protection. This discovery marked the beginning of IML technology phone cases.

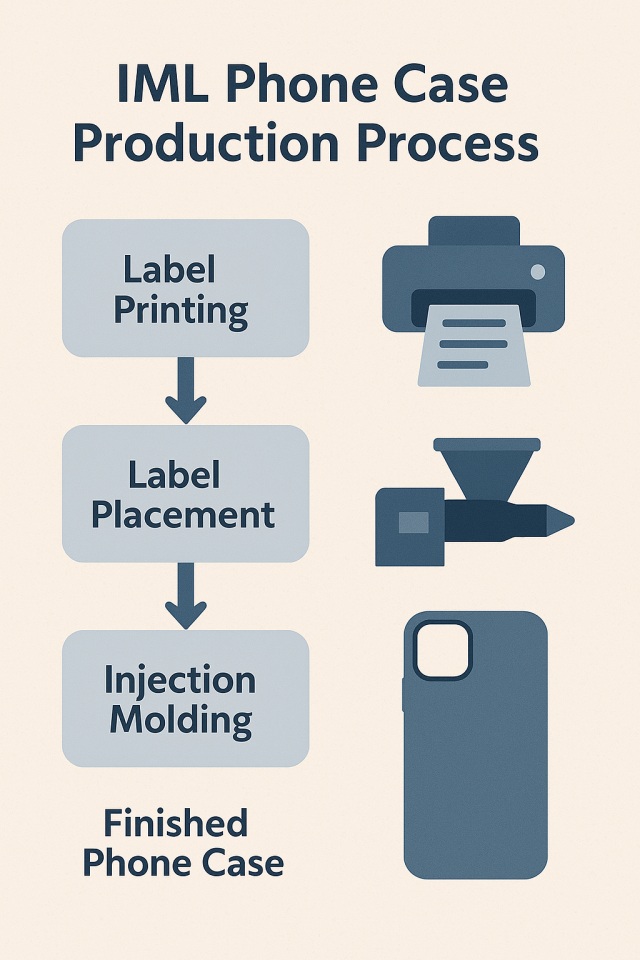

The IML Process Explained

To understand how an IML phone case is created, it’s important to know how the process works:

- Design Creation

The first step is designing the artwork. This can include patterns, graphics, logos, and textures. The design is then printed on a special label or film. - Label Placement

The printed label is carefully placed inside the mold. This requires precision to ensure correct alignment. - Injection Molding

Next, molten plastic is injected into the mold. The heat and pressure cause the label to bond permanently with the plastic. The result is a phone case where the design becomes part of the surface. - Finishing and Quality Check

Once the case cools and solidifies, it undergoes finishing and quality checks. Only high-quality phone cases pass this stage and move on to packaging.

Why IML Technology Is Popular for Phone Cases?

- Enhanced Durability

Since the label is embedded within the plastic, it won’t scratch, peel, or fade easily. This makes IML cases more durable than those with surface printing. - High-End Appearance

Phone case manufacturers can achieve vibrant colors, 3D effects, and metallic finishes with IML. This helps brands offer more visually appealing products. - Cost-Effective Production

For production case companies, IML combines decoration and molding into one step. This improves efficiency and reduces labor costs, especially for large production runs. - Eco-Friendly Benefits

IML eliminates the need for adhesives and coatings, which can be harmful to the environment. Additionally, IML cases are easier to recycle.

Overcoming Challenges

Developing IML technology phone cases was not without challenges. Early on, phone case molds were not optimized for IML. The labels were often misaligned, and achieving consistent quality was difficult.

To overcome these issues, phone case manufacturers invested in advanced equipment and cleanroom environments. They also refined label materials and adhesives to ensure strong bonding and perfect alignment. Today, IML production has become more reliable and accessible.

The Impact on the Phone Case Industry

The introduction of IML technology has transformed the high-quality phone case market. Now, brands can offer custom designs with excellent durability and finish. Consumers, in turn, enjoy phone cases that look good and last longer.

Moreover, IML has allowed smaller brands and independent designers to enter the market. With lower setup costs and flexible design options, even niche products can be produced efficiently.

Conclusion

So, how did an IML technology phone case come into being? It was a result of innovation, cross-industry learning, and the drive to meet changing consumer expectations. From packaging to phone accessories, IML has proven its value.

Today, phone case manufacturers and production case companies continue to explore new ways to leverage IML. As technology improves, we can expect even more creative and durable high-quality phone cases to emerge.

If you’re a brand looking to stand out, adopting IML could be your next big move. The journey of IML in the phone case industry is just beginning — and it’s one worth watching.