In today’s saturated phone case market, choosing the right partner can make or break your product success. Whether you’re launching a magnetic phone case, building a sustainable line of environmentally friendly phone cases, or scaling an existing accessory brand, finding a reputable manufacturer isn’t just a cost decision—it’s a strategic one. So, how do you cut through the noise and find the right phone case partner?

What to Look for in a Reputable Phone Case Manufacturer

Before you dive into product development, vetting your partner is essential. Here’s what experienced brands focus on:

- Manufacturing Capabilities and Product Range

The phone case category isn’t one-size-fits-all. A reputable phone case manufacturer should offer:

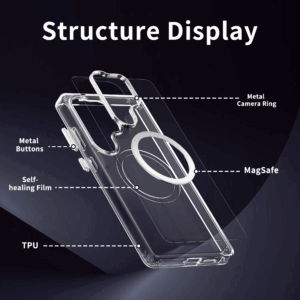

- Injection molding for PC, TPU, or hybrid materials

- Magnetic alignment (for MagSafe-compatible products)

- CNC machining for precision metal components

- Custom mold development

Stat to note: According to IBISWorld, the global mobile phone accessory market surpassed \$85 billion in 2024, and 28% of that revenue was driven by customizable or branded cases. That means having a partner who can support niche demands like magnetic phone case production is no longer optional.

- Material Compliance and Sustainability

Consumers are increasingly looking for environmentally friendly phone case options. If your partner can’t offer recycled TPU, biodegradable polymers, or packaging made from FSC-certified paper, you may fall behind market expectations.

Real-world benchmark: Pela Case, one of the leading sustainable brands, reports that eco-conscious shoppers make up 35% of their returning customers. Manufacturers aligned with environmental standards (RoHS, REACH) show not just compliance, but a forward-looking approach.

- Quality Control and Certifications

Ask to review:

- ISO 9001 certification

- QC procedures (in-line + final inspection)

- Testing reports (drop resistance, magnetic strength, UV resistance, etc.)

Having a quality assurance team embedded in the process ensures consistency, especially if you’re ordering 10,000+ units at a time.

- Transparency in Communication and Lead Times

A strong partner provides clear timelines for mold development, sample delivery, and mass production. For example, a typical development timeline for a custom magnetic phone case should be:

- Mold design: 5–7 days

- Sampling: 7–10 days

- Mass production: 15–20 days

Delays here often indicate disorganization or overcapacity—both are red flags.

Case Study 1: D2C Brand Scaling from 500 to 20,000 Units/Month

A U.S.-based lifestyle brand specializing in minimalist iPhone cases partnered with a Chinese OEM in 2022. Their biggest challenge? Poor product consistency and long lead times.

After switching to a reputable phone case manufacturer with in-house tooling and magnetic module assembly, they:

- Reduced production time by 22%

- Improved defect rate from 5.3% to 0.7%

- Achieved 18% cost savings due to lower remake and return rates

Takeaway: A reliable partner should contribute operational efficiency, not add risk.

Case Study 2: Environmental Brand Launching a New Eco-Friendly Line

In 2023, a Canadian company launched a Kickstarter campaign for an environmentally friendly phone case made from flax-based bioplastic. Their first batch, sourced from an unvetted supplier, failed EU compliance testing.

After conducting a supplier audit and switching to a certified manufacturer with prior experience in plant-based plastics, they passed regulatory tests and completed fulfillment on time.

Lesson learned: Material innovation needs manufacturing support with proven track records.

Case Study 3: Custom Magnetic Phone Case for Retail Chains

A European accessories distributor wanted a custom magnetic phone case line for offline retail. Their key concern was magnetic strength not degrading over time.

Their partner implemented a two-layer N52 magnet module embedded directly into the case body, combined with automated alignment testing. This led to:

- A 30% increase in attach rate for matching accessories

- Less than 1% warranty claim rate across 50,000+ units sold

FAQ

What makes a phone case manufacturer “reputable”?

A reputable phone case manufacturer offers verifiable certifications (like ISO), transparent pricing, responsive communication, and consistent quality control.

How do I evaluate if a supplier can handle magnetic phone cases?

Ask about magnet type (N52 preferred), automated testing protocols, and if they offer MagSafe compatibility. Request a technical drawing and test video sample.

Are environmentally friendly phone cases more expensive?

Not necessarily. While materials like PLA or recycled TPU may carry a slight premium, long-term savings often come from brand value and reduced environmental compliance risk.

Can small brands also work with top-tier manufacturers?

Yes. Some high-quality factories offer low MOQ (500–1000 units) for startup brands. Clear communication and shared vision help bridge the scale gap.

Contact Us

Looking for a dependable phone case manufacturing partner? Visit Runsuncase to explore our custom solutions in magnetic phone case design, eco-friendly material sourcing, and OEM/ODM production.