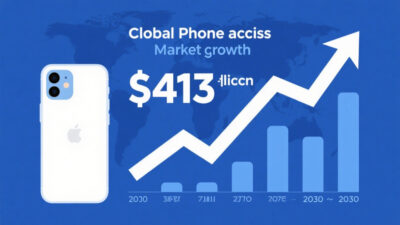

Introduction: Why the Right Manufacturer Matters

In today’s competitive mobile accessories market, choosing the wrong phone case manufacturer can lead to missed deadlines, poor quality, and lost customers. According to Statista, the global smartphone accessories market is projected to reach $413 billion by 2030, driven largely by the demand for protective and stylish phone cases. This means your ability to compete relies heavily on the manufacturer you choose. For any phone case brand aiming to grow sustainably, securing a reliable manufacturing partner is not just important—it’s essential.

1. Quality Standards and Material Expertise

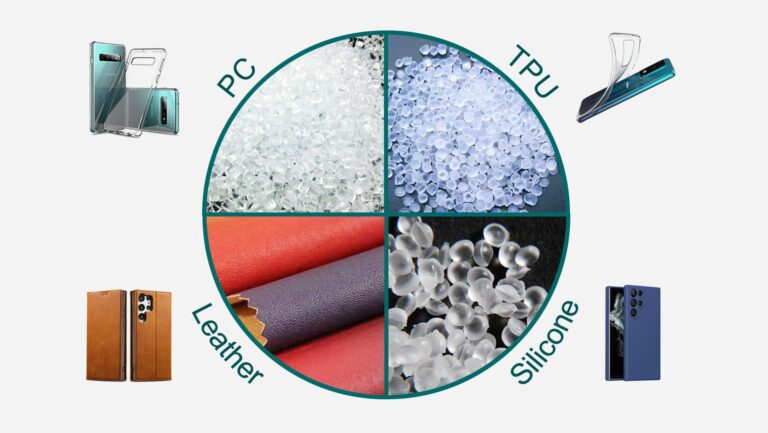

When evaluating phone case manufacturers, the first priority should be product quality. Consumers are increasingly concerned about durability, eco-friendliness, and safety. A 2024 survey by Deloitte found that 56% of U.S. consumers would pay more for sustainable materials.

Look for manufacturers with:

- Certificationslike ISO 9001 for quality management.

- Experience with advanced production techniques (e.g., IML, liquid silicone molding, biodegradable plastics).

- Rigorous QC processes, including drop tests and UV yellowing resistance.

For example, some manufacturers use military-grade drop test standards (MIL-STD-810G), ensuring the phone case can survive multiple 1.2-meter drops without structural damage. This is especially critical for brands targeting the premium segment.

2. Production Capacity and Lead Times

A great design means nothing if your manufacturer can’t deliver on time. Many B2B buyers underestimate how seasonal demand spikes—like holiday sales or new phone launches—can strain a factory’s capacity.

According to market research from IBISWorld, phone accessory demand spikes up to 30% during September and October (post-iPhone launch). A reliable manufacturer should:

- Offer flexible production schedulingto handle volume fluctuations.

- Provide clear lead time commitments(e.g., 2–4 weeks for standard orders).

- Maintain adequate raw material inventory to avoid supply delays.

A real-world example: Runsuncase, a manufacturer specializing in B2B phone case production, has scaled production during peak seasons without compromising delivery timelines—something smaller workshops often can’t achieve.

3. Customization Capabilities for Brand Differentiation

In a crowded market, customization can be your competitive edge. Whether it’s unique textures, branded packaging, or eco-friendly materials, your manufacturer’s flexibility determines how well your products stand out.

Consider:

- Design Support:In-house design teams that can translate your concept into production-ready files.

- Material Variety:From leather and TPU to plant-based PLA plastics.

- Printing Techniques:UV printing, heat transfer, embossing, and debossing for logo application.

A 2023 Shopify report highlighted that customized products have a 28% higher repeat purchase rate compared to mass-market designs. Partnering with a manufacturer who can quickly prototype and adjust designs ensures you can respond to trends without long delays.

4. Transparent Pricing and Long-Term Cost Efficiency

Price is important, but the cheapest option is rarely the best in the long run. Transparent pricing helps avoid hidden costs like rushed shipping fees, extra mold charges, or post-production defect returns.

Look for:

- Detailed quotes covering tooling, materials, and labor.

- Volume-based discounts without compromising quality.

- Clear warranty or defect replacement policies.

A real-world example: Runsuncase phone case factory has scaled production during peak seasons without compromising delivery timelines.

5. Communication and After-Sales Support

Strong communication can prevent most supply chain headaches. You want a manufacturer that responds promptly, shares progress updates, and offers after-sales support for defective units or urgent reorders.

Practical indicators of good communication:

- Dedicated account managers.

- Weekly production updates during large orders.

- Multilingual support for global buyers.

As a phone case brand, you’ll find that a manufacturer who communicates well becomes a strategic partner, not just a supplier.

FAQ: Finding the Right Phone Case Manufacturer

Q1: How can I verify a phone case manufacturer’s reliability before placing a big order?

Check their certifications, request samples, and ask for references from other clients. You can also visit their factory or use third-party inspection services.

Q2: What’s the average lead time for custom phone case manufacturing in China?

For established manufacturers, standard orders may take 2–4 weeks, while complex custom designs may require 5–6 weeks, including prototyping.

Q3: Can small brands work with wholesale phone case manufacturers?

Yes, many manufacturers, such as Runsuncase, accept smaller MOQs (Minimum Order Quantities) for new clients while maintaining the same production standards.

Q4: Are eco-friendly phone case manufacturers producing cases as durable as traditional plastics?

Yes, with the right formulation, materials like biodegradable TPU or recycled ocean plastic can meet durability standards while reducing environmental impact.

Final Thoughts

Finding the right phone case manufacturer requires balancing quality, speed, customization, and communication. The most successful brands partner with manufacturers who can grow with them, adapting to market changes while maintaining consistent standards. Whether you’re launching a niche collection or scaling globally, a stable, trustworthy partner like Runsuncase can be the difference between a short-lived trend and a sustainable business.