In today’s mobile accessory market, consumers aren’t just looking for protection—they want expression. That’s where In-Mold Labeling (IML) steps in, enabling the creation of custom printed phone cases that combine visual impact, durability, and scalable production.

What Is IML?

In-Mold Labeling (IML) is a manufacturing process that embeds a printed film directly into a plastic product during molding. Unlike surface stickers or post-molding prints, IML permanently integrates the design into the case, ensuring long-lasting vibrancy and a sleek, premium finish.

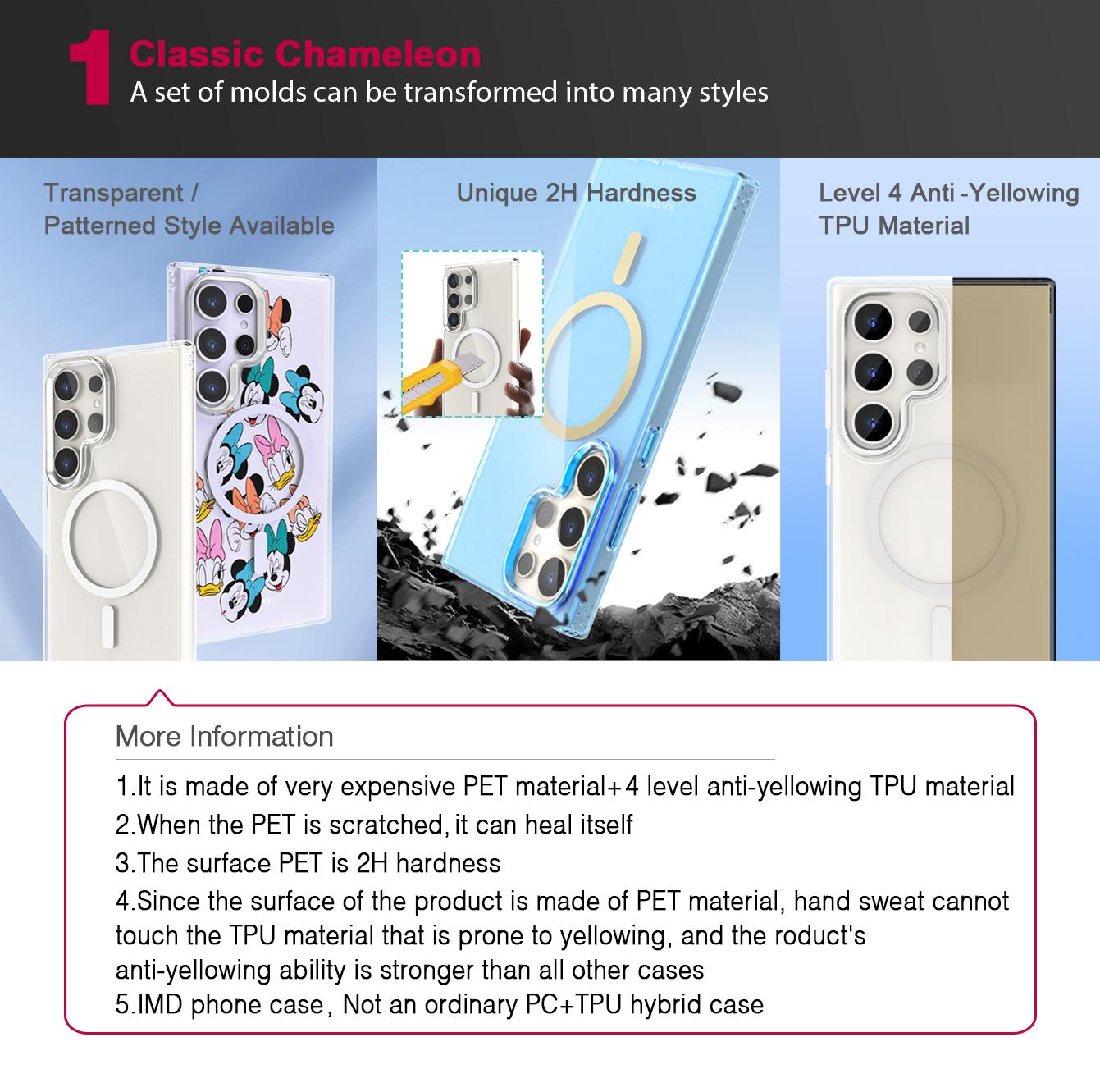

The Perfect Match for Personalized Phone Case Printing

IML is especially suited for personalized phone case printing, allowing brands and users to showcase unique graphics, logos, or artwork on each case. Whether launching a fashion collection or offering user-generated designs, IML ensures that each custom phone case maintains high visual fidelity and scratch resistance.

Anatomy of a Personalized IML Phone Case

Each IML phone case consists of three key layers:

- Protective Film: A durable PET layer that guards against abrasions and enhances appearance.

- Printed Graphic Layer: Your artwork—be it illustrations, branding, or patterns—is applied here using precision printing.

- Plastic Shell: Typically made from PC, ABS, or PMMA to ensure rigidity and protection.

This layered construction turns every case into a long-lasting product that showcases personal style.

How IML Enables Scalable Custom Phone Case Production

- Design & Printing

Custom visuals are printed onto PET film using high-resolution techniques. - Thermoforming

The printed film is molded to match the exact shape of the phone case. - Film Insertion

The shaped film is placed inside the injection mold cavity. - Plastic Injection

Plastic is injected under pressure, permanently fusing with the film. - Trimming & Quality Control

The finished custom-printed phone case is trimmed and inspected for quality assurance.

This process merges decoration and production, making personalized phone cases easier to produce at scale.

Why IML Is Ideal for Custom and Personalized Phone Cases

- Striking Visuals

Enables high-resolution, full-color artwork with consistent quality. - Built for Everyday Use

The integrated graphics won’t peel or fade over time. - Eco-Friendly Manufacturing

No need for additional adhesives or coatings, reducing waste. - Efficient for Personalized Production

Perfect for small-batch or mass-customization models, such as online custom phone case platforms.

Future Trends in Personalized Mobile Accessories

As consumers demand even more uniqueness, personalized phone case printing will evolve with smart features, bio-material films, and real-time design tools. IML’s ability to adapt makes it an essential part of this future, whether you’re serving an individual creator or managing thousands of custom SKUs.

Final Thoughts

For businesses aiming to offer beautiful, durable, and truly personalized phone cases, IML provides a powerful blend of design freedom and production efficiency. It’s more than just a manufacturing method—it’s the foundation for scalable, premium customization in the mobile accessories market.

FAQ

How does IML printing differ from UV printing on phone cases?

IML embeds the printed design directly into the plastic during molding, resulting in better wear resistance and a seamless finish. UV printing, on the other hand, applies ink on the surface, which is faster but may scratch or fade over time, especially on high-contact areas.

Is IML suitable for personalized phone cases with complex graphics or gradients?

Absolutely. IML can reproduce high-resolution images, color gradients, and even photorealistic designs. This makes it ideal for brands offering personalized phone cases that require vivid visuals, such as artwork, photos, or branded color palettes.