When selecting a phone case, most users focus on appearance and basic protection. But for businesses—whether retailers, distributors, or corporate buyers—the decision requires deeper consideration. The right phone case is not only a protective layer but also a product that must meet performance, customization, and market expectations.

As an experienced phone case manufacturer, we share the key factors every buyer should consider when choosing or sourcing a phone case, especially in bulk or for branded customization.

1. Protection Level: It Starts with Functionality

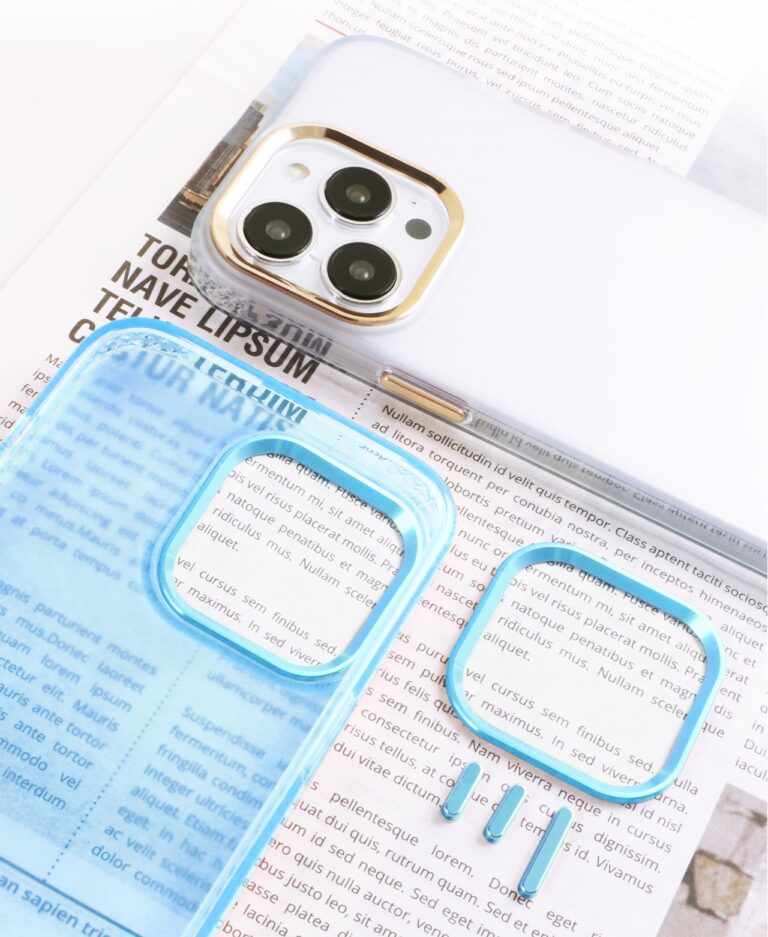

A quality protective phone case must do its job—prevent damage. Key protection aspects include:

- Shock Absorption: Materials like TPU or silicone can disperse impact from drops.

- Scratch Resistance: Polycarbonate or hard-shell surfaces reduce daily wear.

- Raised Edges: Protects the screen and camera when laid flat.

- Structural Integrity: Dual-layer or hybrid construction ensures lasting durability.

2. Material Selection: Balance Cost, Performance, and Design

Different industries demand different materials. When sourcing bulk phone cases, understanding the use case helps select the right base material:

| Balance Cost, Performance, and Design | ||

| Material | Features | Recommended Use Case |

| TPU | Flexible, impact-resistant | General protection, youth market |

| PC (Polycarbonate) | Rigid, lightweight, scratch-resistant | Slim-fit designs, corporate gifting |

| Silicone | Soft-touch, grippy feel | Promotional, entry-level lines |

| Leather (PU/Genuine) | Premium look, business use | Executive or luxury lines |

3. Customization Options: Build Your Brand Identity

For many B2B customers, the value of a custom phone case lies in branding. Consider these customizable elements:

- Logo Printing (Silk Screen / UV / Debossing)

- Color Matching (Pantone or CMYK)

- Surface Finish (Matte, Glossy, Textured)

- Packaging Design (Retail-ready, eco-friendly, OEM)

4. Device Compatibility and Fit Precision

A good phone case must fit the target model precisely. Issues with cutouts or button response can damage your brand credibility.

At the manufacturing level, we ensure:

- Accurate 3D modeling for new phone models

- Ongoing mold updates for flagship devices

- Compatibility with wireless charging and accessories

5. Bulk Supply Capability & Quality Control

Businesses rely on consistency. A reliable phone case supplier must provide:

- Stable monthly output and lead time

- International standards (RoHS, REACH, ISO, etc.)

- 100% inspection or AQL sampling

- Clear warranty and after-sales support

Final Thoughts about Choosing the Right Phone Case Supplier

Whether you’re sourcing for resale, brand promotion, or corporate gifting, choosing the right phone case involves more than design. Consider protection, material, customization, and supply reliability. As a professional custom phone case manufacturer, we’re here to help you deliver products your customers can trust — and remember.

Looking for Custom Phone Cases in Bulk? Let’s build your product line together.

Contact Us for OEM/ODM Services → Runsun case